PPS Group a.s. has its own accredited calibration and testing laboratory, which is accredited according to the international standard ISO/IEC 17025:2017. The calibration laboratory is capable of performing calibration of length, plane angle, temperature and pressure gauges. The test laboratory is capable of measuring geometric quantities, shape and position deviations on three-dimensional coordinate measuring machines (3D). We provide calibration and testing laboratory services not only within our own company but also for customers of other companies. In order to win customer satisfaction and trust and to improve the quality of the work of the calibration and testing laboratory, we constantly monitor and apply new knowledge gained at regular seminars and training courses.

The metallographic laboratory of PPS Group a.s. carries out activities to improve the quality of products manufactured by the company by providing a comprehensive control of supplied materials through mechanical and metallographic tests.

The scope of the accredited activities is metallographic analysis of materials and welded joints.

| Name of measuring instrument | Type | Scale |

|---|---|---|

| Universal length gauge | ULM 600-C | 0-600/100 mm |

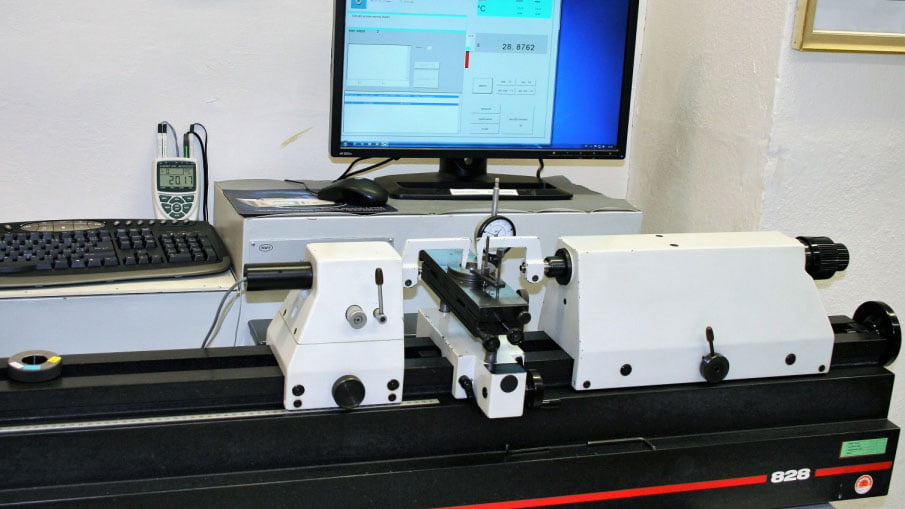

| Universal length gauge | Mahr 828 | 0-1000 mm |

| Universal length gauge | SIP MUL 1000, | 0-1000 |

| Universal length gauge | ULM 1000, | 0-1000 |

| Altimeter | Digimar 817 CLM | 0-600 |

| Altimeter for end gauge calibration | Mahr 826 | 0-125 |

| Altimeter | ABBE 200S | 0-200/100 mm |

| Altimeter | ABBE P0 | 0-200/100 mm |

| Universal measuring microscope | UMM 200 | 200×100 mm |

| Altimeter for calibrating angles | Rectimar 830 | 700 |

| Three-coordinate measuring machine | MORA 0151 | 0-3300 |

| Three-coordinate measuring machine | Leica AT901-MR | 0-40000 mm |

| Pressure gauge | M2200/SP, | 0,01-70 MPa |

| Optical dividing head | P1 | 0-360° |

| Dividing device | WTGM | 0-360° |